Latest News

MOBILE

The transport layer will play an important part in defining the success of 5G as it did in previous mobile generations. Microwave will play a key role in complementing operator’s fiber footprint.

IPS & Private

Flexibility, security and fast time to service a key requirement in mission critical networks. Microwave radio offers immediate connectivity, fibre like capacity and encrypted signals for highest security.

MICROWAVE

Complete microwave radio portfolio including split mount, full outdoor and all indoor systems across traditional licensed bands and millimetre wave, supporting MEF, IP/MPLS and SDN protocols.

SDN

Software defined networks A standard domain controller to supervise and export the underlying network connectivity to higher orchestration layers for simple end 2 end services setup network automations enablement.

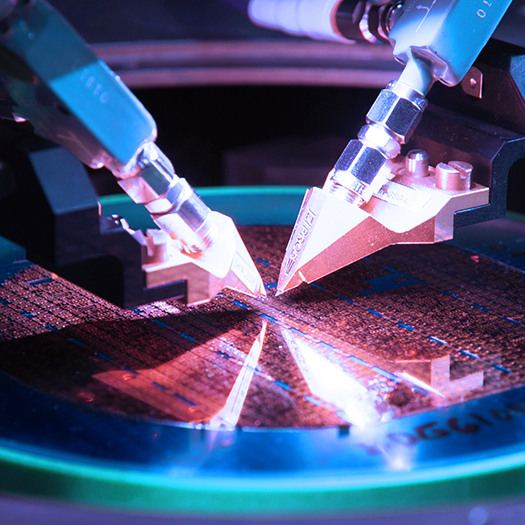

RF DESIGN

In-House RF and Digital Design Labs to design and develop highest performance components to push the technology edge forward and maintain competitive advantage.

SERVICES

A comprehensive portfolio of service solutions to assist in the design, the deployment and the optimization of any network, supporting the entire network lifecycle.